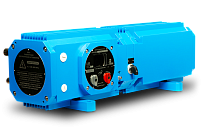

Maritime application actuators

The RemTEK electric drives for maritime application have the climatic versions М1 and ОМ1

Fill in the questionnaire

Characteristics

Designation:

RemTEK electric drives of marine design have climatic groups M1 and OM1 and can be used on ships and offshore platforms for oil and gas production, as well as installed in the coastal zone on the mainland.

RemTEK electric drives meet the technical requirements of the "Rules for the classification, construction and equipping the floating drilling rigs and fixed offshore platforms" of the Russian Maritime Register of Shipping.

Environmental Durability:

- Normal operation at temperatures within the range from -63 to +50 °С;

- Normal operation at relative air humidity (75±3)% and temperature (45±3) °С, or at relative air humidity (80±3)% and temperature (40±3) °С.

Power Supply:

- Connection via IT power system, 3 ~ 50 Hz, 380 V (without neutral conductor);

- Ensuring reliable operation where fluctuations of the supply network are from -50% to + 47%;

- Resistance to μs-, ns-interference and static electricity. Performance criterion А.

Electric Motor:

- Motor winding insulation of RemTEK electric drives is class H;

- Stator windings are provided with selfheating unit.

Resistance to Environment Exposure:

- Shell and fastenings made from corrosion-resistant materials;

- Anodic and chemical oxidation of electric drive parts to create an additional protective barrier against corrosion;

- Paint coating system certified by the Russian Maritime Register of Shipping;

- Compliance of the coating system with the requirements for zone C5-M according to ISO12944;

- Three-layer coating system: epoxy primer and two coats of epoxy enamel;

- Solar radiation resistance;

- Salt fog resistance;

- Mold fungi resistance;

- Coating durability is at least 15 years.

Up-to-date Solutions for Mechanical Transmissions:

- Cycloidal transmissions;

- Transmissions with intermediate rolling elements;

- Ball screws:

- Feed nut assemblies with anti-friction materials;

- Parallel-shaft reduction gear units;

- High efficiency: 0.85–0.9;

- Co-axial arrangement of the drive; no console;

- Proprietary solution.

Specifications:

| Type | linear, part-turn, multi-turn |

|

Valves to be automated |

for all types |

| Valve diameter | DN 15 - 1200 mm |

| Version | explosion proof 1 Ex d IIB T4 Gb Х |

| Torque |

40 – 10000 Nm 1000 – 65000 N |

| Supply voltage | 400 V (230 V) |

|

Coatings |

C5-M area as per ISO12944 |

|

paining coatings are certified by RMRS |

|

| Service life of coatings |

not less than 15 years |

Gallery

.png)