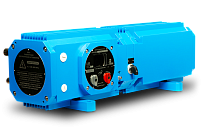

Actuators with safe function

Control of stop, cut-off or control valves with shutter position in a safe condition when removing power supply

Fill in the questionnaire

Designation:

The electric drive is designed to control shut-off, cut-off and control valves with bringing the valve gate to a safe position when the power supply is removed or a command is issued to move into the safe position.

Functions:

• Adjustable by user “normal” state: open, closed, safety position.

• Routine function to implement adjustments at low speeds with high frequency maintenance of the position and fast moving to the safety position at a preset speed.

• Combining a high efficiency gearbox, a highly efficient permanent magnet synchronous brushless motor and an in-built frequency converter allows using an in-built electric power storage unit, which ensures moving the output link of the electric drive to the required position.

• Energy storage in reliable supercapacitors with a double dielectric layer, where the guaranteed number of charge-discharge cycles is 50,000.

• Energy reserve from 1 to 10 travel cycles of the output link depending on the version of the electric drive and valve used.

• Compliance with the requirements of STO GAZPROM 2-4.1-212-2008 in terms of valve overlap time and compliance with the requirements for technological units of the I category of explosion safety in accordance with OPB (Federal Law No. 96 d/d 11.03.2013).

• Maintenance of the energy storage unit is not required during its entire service life.

• Compliance with functional safety standards according to GOST R IEC 61508 and GOST R IEC 61511 at the SIL2 level.

Features and Benefits:

• A block of supercapacitors built into the shell of the electric drive with secondary power and charge sources;

• Capability to equip a linear or part-turn electric drive with the "NO_NC" block of a standard design;

• High-efficient self-controlled synchronous electric motor with permanent magnets;

• In-built frequency converter;

• Cycloidal gearboxes and gearboxes with intermediate rolling elements;

• Universal control unit for all modifications of electric drives;

• In-built WIFI interface; ready to “Digital Economy”, “Industry 4.0 Ready”;

• Double insulated connection box.

Specifications

| Type | Linear, part-turn |

|

Valves to be automated |

for all types |

|

Valve diameter |

DN 15-400 mm |

|

Version |

explosion proof 1ExdIIBT4 Х |

|

Torque |

40 – 2000 Hm 1000 – 45000 Н |

|

Supply voltage |

400 V AC or 230 V AC |

|

Operating temperature |

from -63 to +50 °С |

|

Time ready to be fired at the security features after power-up |

5 min |

|

Bypass power supply circuit |

Yes. The equipment is ready for operation after switching on the input network |

|

Integration into the automated process control system |

Digital inputs, outputs, RS-485 interface (Modbus RTU), analog control and feedback signals |

- Part-turn

- Linear

|

Modifications |

Torque limitation range, N | Shut off time, sec | |||

|

RemTEK.P.75

|

15...75 |

6...60 |

|||

|

RemTEK.P.125

|

30...125 |

||||

|

RemTEK.P.250

|

50...250 |

||||

|

RemTEK.P.600

|

120...600 |

||||

|

RemTEK.P.1000

|

200...1000 |

||||

|

RemTEK.P.2000

|

400...2000 |

9...100 |

|

Modifications |

Torque limitation range, N |

Speed at the gearbox output, m / s | |||

|

RemTEK.L.3500

|

700...3500 |

1...20 |

|||

|

RemTEK.L.7000

|

1400...7000 |

||||

|

RemTEK.L.10000

|

2000...10000 |

||||

|

RemTEK.L.18000

|

3600...18000 |

||||

|

RemTEK.L.25000

|

5000...25000 |

||||

|

RemTEK.L.30000

|

6000...30000 |

||||

|

RemTEK.L.45000

|

9000...45000 |

.png)