Electric drives powered by 24V DC

Control of valves in systems with renewable power sources. Direct connection to an energy storage system without additional converters.

Fill in the questionnaire

Purpose:

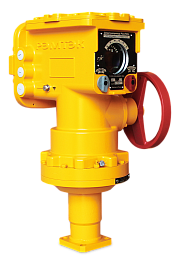

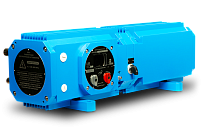

Explosion-proof intelligent electric drive for controlling any type of pipeline fittings in systems with renewable power sources (RES) and a supply voltage of 24 V DC.

Functions:

• Built-in electronic limit and torque switches• Built-in frequency converter for motion control

• Reliable mechanical transmissions

• Function of bringing to a safe position;

• Analog and discrete control;

• Management and configuration via interface;

• Intelligent monitoring and protection system;

• Volatile electronic position sensor;

• Configuration without opening the shell;

• Double insulation of the connection box;

• No mechanical contacts.

Features and Benefits:

• Application of synchronous electric motors with permanent magnets

• Drive energy efficiency due to highly efficient gears

• Wide range of supply voltages

• Function for limiting power consumption from the power supply

• Remote configuration and monitoring technologies (DTM)

• Availability of built-in WIFI interface; ready for the Digital Economy, Industry 4.0 Ready;

• Compact size and monoblock design of the electric motor and control electronic unit;

• Highly reliable cycloidal gears and gears with intermediate rolling elements, ball screws;

• High reliability and fault tolerance;

• Self-diagnosis, built-in archiving of emergency events

• Partial valve stroke test (PST-test);

• Compliance with functional safety standards according to GOST R IEC 61508 and GOST R IEC 61511 at the SIL2 level.

Specifications:

| Type | linear, part-turn |

|

Valves to be automated |

for all types |

| Valve diameter | DN 15 - 700 mm |

| Version | explosion proof 1 Ex d IIB T4 Gb Х |

| Torque |

40 – 90000 Nm 3500 – 220000 N |

| Supply voltage | 24 V DC (range from 12 V to 36 V) |

|

Operating temperature |

from -63 to +50 °С |

|

Time ready to be fired at the security features after power-up |

5 min |

|

Integration into the automated process control system |

Digital inputs, outputs, RS-485 interface (Modbus RTU), analog control and feedback signals |

|

Supports DTM and remote configuration and monitoring technology |

Yes |

- Multi-turn

- Part-turn

- Linear

|

Electric drive type |

MAX torque, Nm |

Shutdown torque setting range, Nm |

Max speed at the gearbox output, rev/min |

Mode s2, min |

Mode s3, OD%; Tc min |

Mode s4, p/h |

Seat type |

|||||

|

RemTEK.M.40.50

|

40 |

8...40 |

50 |

30 |

25%, 60min |

1200 |

А |

|||||

| RemTEK.M.40.70 |

70 |

30 |

25%, 60min |

1200 |

||||||||

|

RemTEK.M.40.110 |

110 |

30 |

25%, 60min |

1200 |

||||||||

|

RemTEK.M.60.80 |

60 |

12...60 |

80 |

30 |

25%, 60min |

1200 |

А |

|||||

|

RemTEK.M.60.100 |

100 |

30 |

25%, 60min |

1200 |

||||||||

|

RemTEK.M.70.40 |

70 |

14...70 |

40 |

30 |

25%, 60min |

1200 |

А |

|||||

|

RemTEK.M.70.70 |

70 |

30 |

25%, 60min |

1200 |

||||||||

|

RemTEK.M.100.45 |

100 |

20...100 |

45 |

30 |

25%, 60min |

1200 |

А(B) |

|||||

| RemTEK.M.120.50 |

120 |

24...120 |

50 |

30 |

25%, 60min |

1200 |

А(B) |

|||||

|

RemTEK.M.150.30 |

150 |

30...150 |

30 |

30 |

25%, 60min |

1200 |

А(B) |

|||||

| RemTEK.M.150.50 |

50 |

30 |

25%, 60min |

1200 |

||||||||

|

RemTEK.M.200.20 |

200 |

40...200 |

20 |

30 |

25%, 60min |

1200 |

А(B) |

|||||

|

RemTEK.M.200.30 |

30 |

30 |

25%, 60min |

1200 |

||||||||

|

RemTEK.M.250.230 |

250 |

50...250 |

230 |

30 |

25%, 60min |

1200 |

B |

|||||

|

RemTEK.M.300.12 |

300 |

60..300 |

12 |

30 |

25%, 60min |

1200 |

B |

|||||

| RemTEK.M.600.6 |

600 |

120..600 |

6 |

30 |

25%, 60min |

1200 |

B(C) |

|||||

| RemTEK.M.1000.3 |

1000 |

200..1000 |

3 |

30 |

25%, 60min |

1200 |

B(C) |

|||||

|

Electric drive type |

MAX torque, Nm |

Shutdown torque setting range, Nm |

Minimum working stroke time, s |

Mode s2, min |

Mode s3, |

Mode s4, p/h |

Seat type |

|||

| RemTEK.P.64 |

64 |

12,8..64 |

1 |

30 |

25%, 60min |

1200 |

F07 |

|||

| RemTEK.P.125 |

125 |

25...125 |

0,4; 3; 4; 6 |

30 |

25%, 60min |

1200 |

F07 |

|||

|

RemTEK.P.250 |

250 |

50..250 |

1; 3; 4; 6 |

30 |

25%, 60min |

1200 |

F07 |

|||

|

RemTEK.P.600 |

600 |

120..600 |

2; 4; 6 |

15 |

25%, 60min |

1200 |

F10 |

|||

|

RemTEK.P.1000 |

1000 |

200..1000 |

3; 6 |

30 |

25%, 60min |

1200 |

F12 |

|||

|

RemTEK.P.2000 |

2000 |

400..2000 |

8; 12 |

30 |

25%, 60min |

1200 |

F14 |

|||

| RemTEK.P.4000 |

4000 |

800...4000 |

16; 24 |

30 |

25%, 60min |

1200 |

F16 |

|||

| RemTEK.P.8500 |

8500 |

1700...8500 |

32; 60 |

30 |

25%, 60min |

600 |

F25 |

|||

| RemTEK.P.10000 |

10000 |

2000...10000 |

36; 60 |

30 |

25%, 60min |

600 |

F25 |

|||

|

RemTEK.P.16000

|

16000 |

8000...16000 |

30; 50; 60 |

30 |

25%, 60min |

600 |

F30 |

|||

|

RemTEK.P.24000 |

24000 |

4800..24000 |

65 |

30 |

25%, 60min |

600 |

F30 |

|||

|

Electric drive type |

MAX moment, Н |

Trip force setting range, Н |

Maximum output speed of the gearbox, mm/s |

Full speed ahead, mm |

Mode s2, min |

Mode s3, |

Mode s4, p/h |

||||

|

RemTEK.L.3500

|

3500 |

700..3500 |

4; 7; 35 |

60 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.7000

|

7000 |

1400..7000 |

4; 7; 15; 35 |

60/100/125/160/200 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.10000

|

10000 |

2000..10000 |

7; 10; 15; 20; 35 |

60/100/125/160/200 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.18000

|

18000 |

3600..18000 |

4; 7; 10; 12; 20; 25 |

60/100/125/160/200 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.25000

|

25000 |

5000..25000 |

6; 10 |

60/100/125/160/200 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.30000

|

30000 |

6000..30000 |

10 |

125/160/200 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.45000

|

45000 |

9000..45000 |

5 |

100/150/220 |

30 |

25%, 60min |

1200 |

||||

|

RemTEK.L.65000

|

65000 |

13000..65000 |

5 |

100/150/220 |

30 |

25%, 60min |

1200 |

||||

.png)