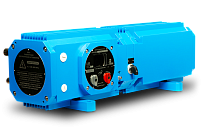

High-speed shut-off electric actuators

The electric drive is designed for fast flow cut-off in technological installations or ESD systems.

Fill in the questionnaire

Designation:

Electric drive is used in ESD systems, safety circuits (SIL2) to control isolation shut-off or control pipeline valves.

It is used at oil gas facilities in explosive zones of class 1 and 2 in accordance with GOST R 60079 (in explosive zones of all classes), where may be formed vapor- and gas-and-air explosive mixtures of IIA and IIB groups T1, T2, T3, T4 as per the classification of GOST R IEC 60079-20-1.

Functions:

- Bringing to a safe position function;

- Analogue and discrete control;

- Control and setting via interfaces;

- Intelligent monitoring and protection systems;

- Absolute electronic position sensor;

- Nonintrusive set up;

- No mechanical contacts.

Features and Benefits:

- Cut off time from 0.2 sec for a ball valves of 90 deg;

- Position regulation at low speed and fast cut-off when safety signal is on;

- Compact size and monoblock design of the electric motor and electronic control unit;

- Reliable, brushless, maintenance-free, synchronous electric drive with peak mechanical power up to 3 kW;

- Energy efficiency due to the built-in frequency converter;

- Highly reliable cycloidal transmissions and transmissions with intermediate rolling elements, ball-screw units;

- High reliability and fail safety;

- Self-diagnosis, built-in archiving of emergency events;

- Embodiments provided with safe state function (NO/NC) with built-in energy storage on supercapacitors;

- Supply voltage: 230 V or 400 V;

- Partial valve stroke test (PST-test);

- Functional safety SIL2.

- Part-turn

- Linear

| Modifications |

Max torque, Nm |

Supply voltage, V |

Minimum overlap time, sec |

Function (NO/NC) |

|||||

|

RemTEK.P.125

|

37,5...125 |

400 |

0,2 / 1 / 3 / 6 / 9 / 12 |

Yes |

|||||

|

230 |

0,3 / 1 / 3 / 6 |

||||||||

|

RemTEK.P.250

|

75...250 |

400 |

0,3/ 1 / 3 / 6 / 9 / 12 |

Yes |

|||||

|

230 |

0,4 / 1 / 3 / 6 / 9 / 12 |

||||||||

|

RemTEK.P.600

|

180...600 |

400 |

0,8 / 3 / 6 / 9 |

Yes |

|||||

|

230 |

1,4/ 3 / 6 / 9 / 12 |

||||||||

|

RemTEK.P.1000

|

200...1000 |

400 |

1 / 3 / 6 / 9 / 12 |

Yes |

|||||

|

230 |

2 / 3 / 6 / 9 / 12 |

||||||||

|

RemTEK.P.2000

|

400...2000 |

400 |

3 / 6 / 9 / 12 |

Yes |

|||||

|

230 |

6 / 9 / 12 |

||||||||

|

RemTEK.P.4000

|

800...4000 |

400 |

6 / 9 / 12 |

No |

|||||

|

230 |

10 / 12 |

||||||||

|

RemTEK.P.8500

|

1700...8500 |

400 |

12 |

No |

|||||

|

230 |

20 / 24 / 30 |

||||||||

|

RemTEK.P.10000

|

2000...10000 |

400 |

16 / 30 |

No |

|||||

|

230 |

18 / 30 |

||||||||

|

RemTEK.P.16000

|

8000...16000 |

400 |

12 / 18 / 24 / 30 |

No |

|||||

|

RemTEK.P.32000

|

6400...32000 |

400 |

18 / 24 / 30 / 36 |

No |

|||||

|

RemTEK.P.63000

|

12600...63000 |

400 |

30 / 36 / 42 |

No |

|

Modifications |

Max torque, Nm |

Max speed at the gearbox output, rev/min |

Move, mm |

Function (NO/NC) |

|||||

|

RemTEK.L.3500

|

3500 |

55/110 |

60 |

Yes |

|||||

|

RemTEK.L.7000

|

7000 |

55/110 |

60/100 |

Yes |

|||||

|

RemTEK.L.10000

|

10000 |

20/55/110 |

200 |

Yes |

|||||

|

RemTEK.L.18000

|

18000 |

20/50/90 |

100/160/200 |

Yes |

|||||

|

RemTEK.L.30000

|

30000 |

20/30 |

125/160/200 |

Yes |

.png)